Final project "Comic strip"

Text z Príbehu

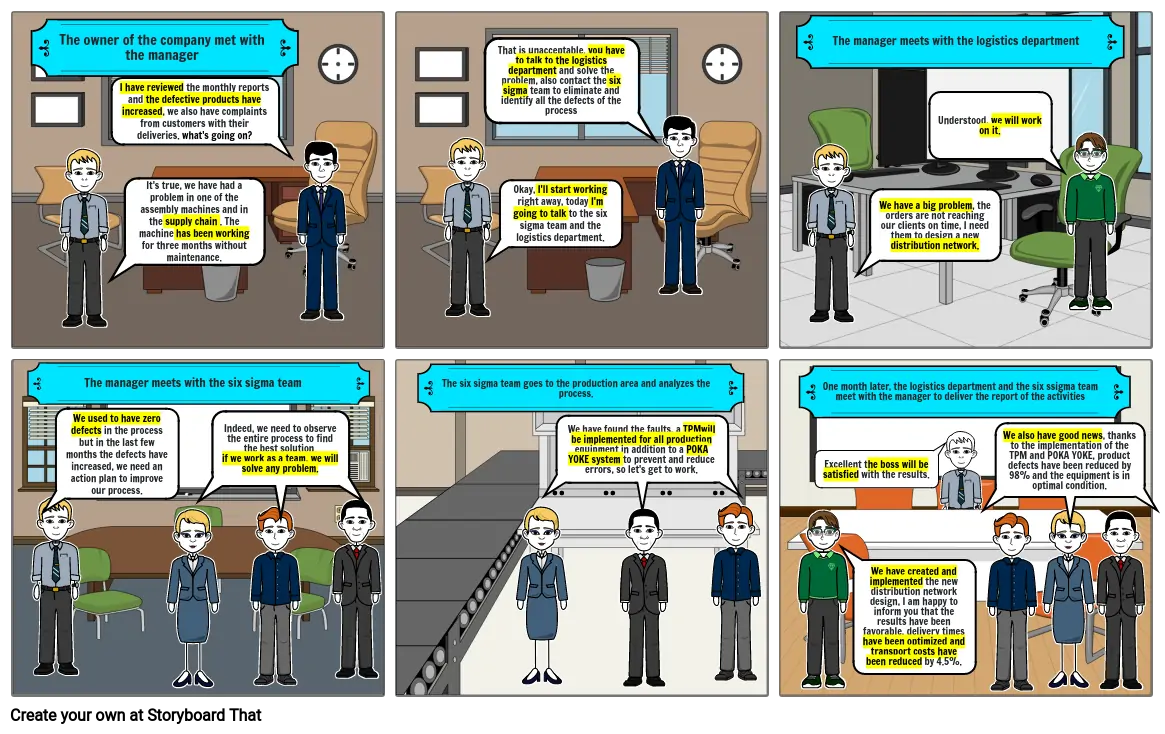

- The owner of the company met with the manager

- It's true, we have had a problem in one of the assembly machines and in the supply chain . The machine has been working for three months without maintenance.

- I have reviewed the monthly reports and the defective products have increased, we also have complaints from customers with their deliveries. what's going on?

- That is unacceptable, you have to talk to the logistics department and solve the problem, also contact the six sigma team to eliminate and identify all the defects of the process

- Okay, I'll start working right away, today I'm going to talk to the six sigma team and the logistics department.

- The manager meets with the logistics department

- We have a big problem, the orders are not reaching our clients on time, I need them to design a new distribution network.

- Understood, we will work on it.

- The manager meets with the six sigma team

- We used to have zero defects in the process but in the last few months the defects have increased, we need an action plan to improve our process.

- Indeed, we need to observe the entire process to find the best solution.if we work as a team, we will solve any problem.

- The six sigma team goes to the production area and analyzes the process.

- We have found the faults, a TPMwill be implemented for all production equipment in addition to a POKA YOKE system to prevent and reduce errors, so let's get to work.

- One month later, the logistics department and the six ssigma team meet with the manager to deliver the report of the activities

- Excellent the boss will be satisfied with the results.

- We have created and implemented the new distribution network design, I am happy to inform you that the results have been favorable, delivery times have been optimized and transport costs have been reduced by 4.5%.

- We also have good news, thanks to the implementation of the TPM and POKA YOKE, product defects have been reduced by 98% and the equipment is in optimal condition.

Bolo vytvorených viac ako 30 miliónov storyboardov