Unknown Story

Siužetinės Linijos Tekstas

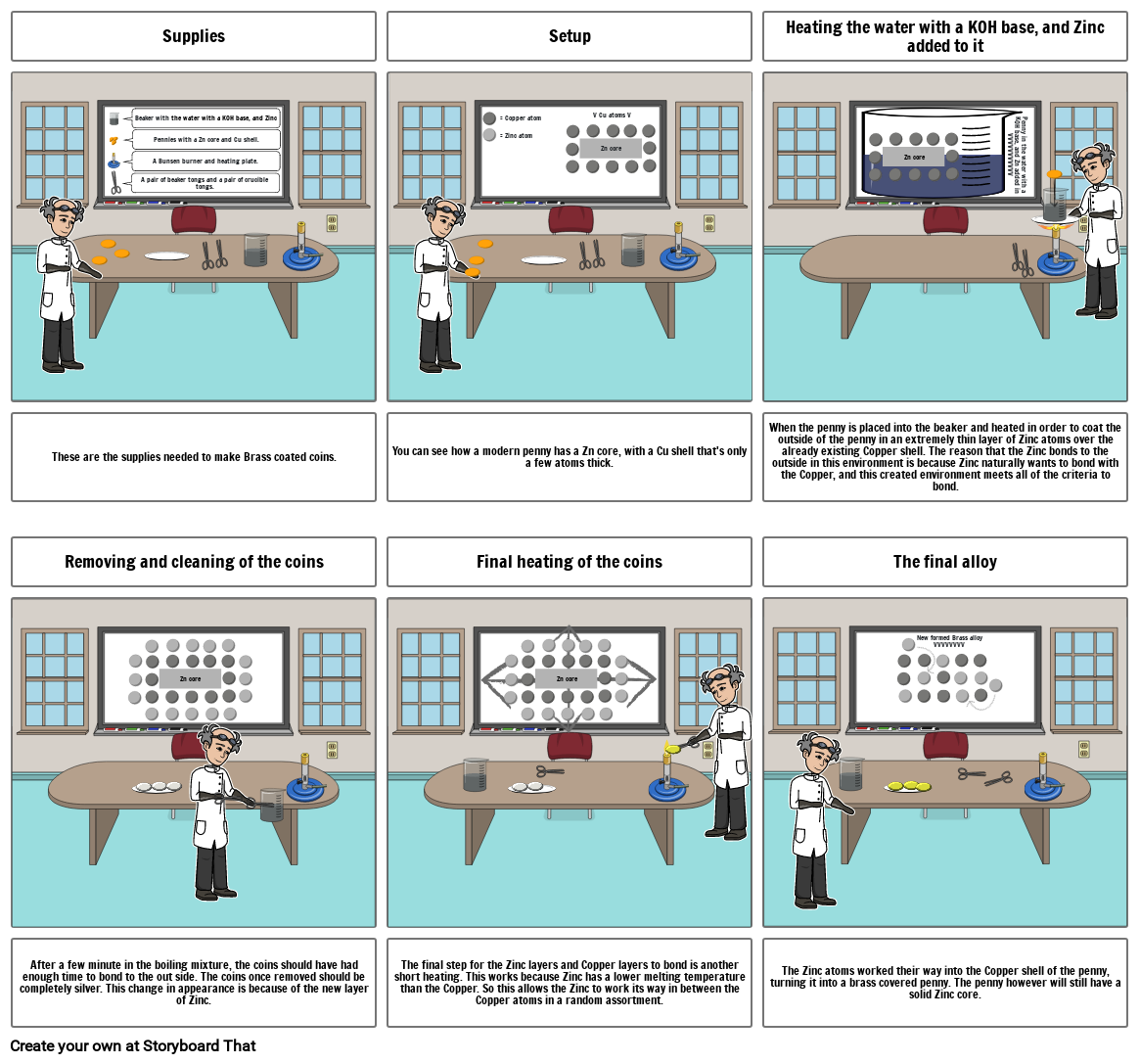

- Supplies

- A pair of beaker tongs and a pair of crucible tongs.

- Beaker with the water with a KOH base, and Zinc

- A Bunsen burner and heating plate.

- Pennies with a Zn core and Cu shell.

- Setup

- = Copper atom

- = Zinc atom

- V Cu atoms V

- Zn core

- Heating the water with a KOH base, and Zinc added to it

- Zn core

- Penny in the water with a KOH base, and Zn added inVVVVVVVVVVV

- These are the supplies needed to make Brass coated coins.

- Removing and cleaning of the coins

- Zn core

- You can see how a modern penny has a Zn core, with a Cu shell that's only a few atoms thick.

- Final heating of the coins

- Zn core

- When the penny is placed into the beaker and heated in order to coat the outside of the penny in an extremely thin layer of Zinc atoms over the already existing Copper shell. The reason that the Zinc bonds to the outside in this environment is because Zinc naturally wants to bond with the Copper, and this created environment meets all of the criteria to bond.

- The final alloy

- New formed Brass alloyVVVVVVVV

- After a few minute in the boiling mixture, the coins should have had enough time to bond to the out side. The coins once removed should be completely silver. This change in appearance is because of the new layer of Zinc.

- The final step for the Zinc layers and Copper layers to bond is another short heating. This works because Zinc has a lower melting temperature than the Copper. So this allows the Zinc to work its way in between the Copper atoms in a random assortment.

- The Zinc atoms worked their way into the Copper shell of the penny, turning it into a brass covered penny. The penny however will still have a solid Zinc core.

Sukurta daugiau nei 30 milijonų siužetinių lentelių