The Mining Process of Aluminium

Storyboard Tekst

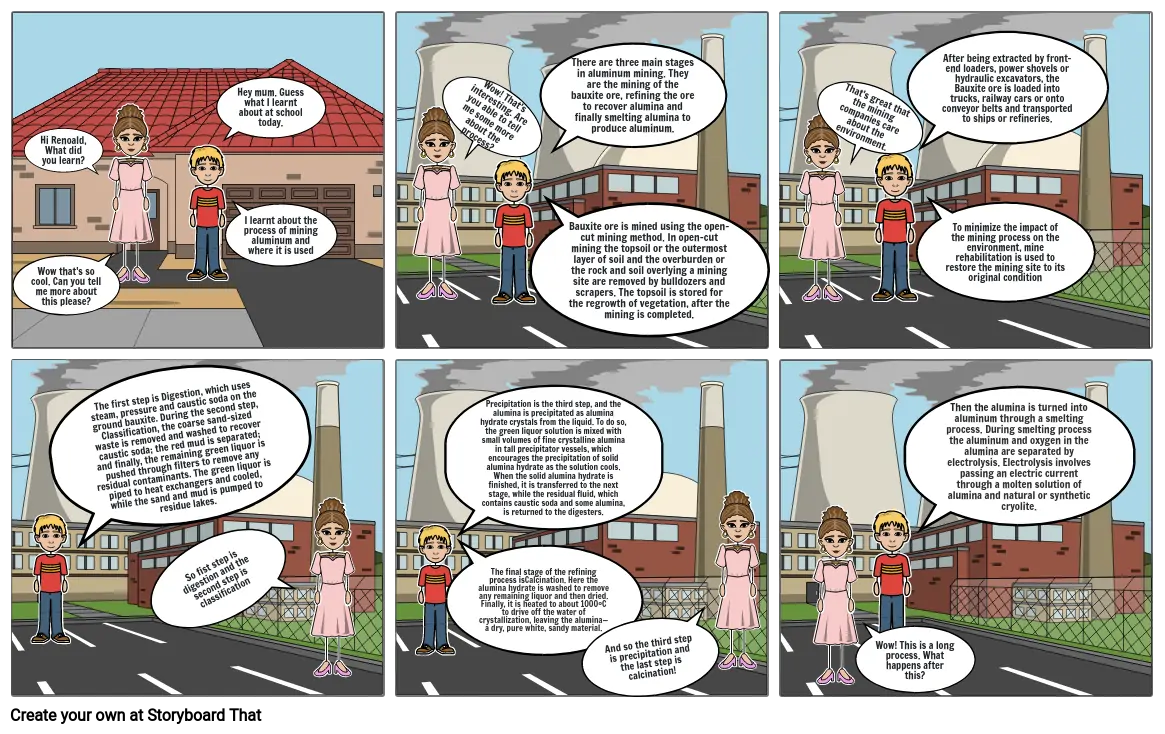

- Wow that's so cool. Can you tell me more about this please?

- Hi Renoald, What did you learn?

- Hey mum. Guess what I learnt about at school today.

- I learnt about the process of mining aluminum and where it is used

- Wow! That's interesting. Are you able to tell me some more about the process?

- Bauxite ore is mined using the open-cut mining method. In open-cut mining the topsoil or the outermost layer of soil and the overburden or the rock and soil overlying a mining site are removed by bulldozers and scrapers. The topsoil is stored for the regrowth of vegetation, after the mining is completed.

- There are three main stages in aluminum mining. They are the mining of the bauxite ore, refining the ore to recover alumina and finally smelting alumina to produce aluminum.

- That's great that the mining companies care about the environment.

- After being extracted by front-end loaders, power shovels or hydraulic excavators, the Bauxite ore is loaded into trucks, railway cars or onto conveyor belts and transported to ships or refineries.

- To minimize the impact of the mining process on the environment, mine rehabilitation is used to restore the mining site to its original condition

- The first step is Digestion, which uses steam, pressure and caustic soda on the ground bauxite. During the second step, Classification, the coarse sand-sized waste is removed and washed to recover caustic soda; the red mud is separated; and finally, the remaining green liquor is pushed through filters to remove any residual contaminants. The green liquor is piped to heat exchangers and cooled, while the sand and mud is pumped to residue lakes.

- So fist step is digestion and the second step is classification

- Precipitation is the third step, and the alumina is precipitated as alumina hydrate crystals from the liquid. To do so, the green liquor solution is mixed with small volumes of fine crystalline alumina in tall precipitator vessels, which encourages the precipitation of solid alumina hydrate as the solution cools. When the solid alumina hydrate is finished, it is transferred to the next stage, while the residual fluid, which contains caustic soda and some alumina, is returned to the digesters.

- The final stage of the refining process isCalcination. Here the alumina hydrate is washed to remove any remaining liquor and then dried. Finally, it is heated to about 1000°C to drive off the water of crystallization, leaving the alumina—a dry, pure white, sandy material.

- And so the third step is precipitation and the last step is calcination!

- Wow! This is a long process. What happens after this?

- Then the alumina is turned into aluminum through a smelting process. During smelting process the aluminum and oxygen in the alumina are separated by electrolysis. Electrolysis involves passing an electric current through a molten solution of alumina and natural or synthetic cryolite.

Izrađeno više od 30 milijuna scenarija