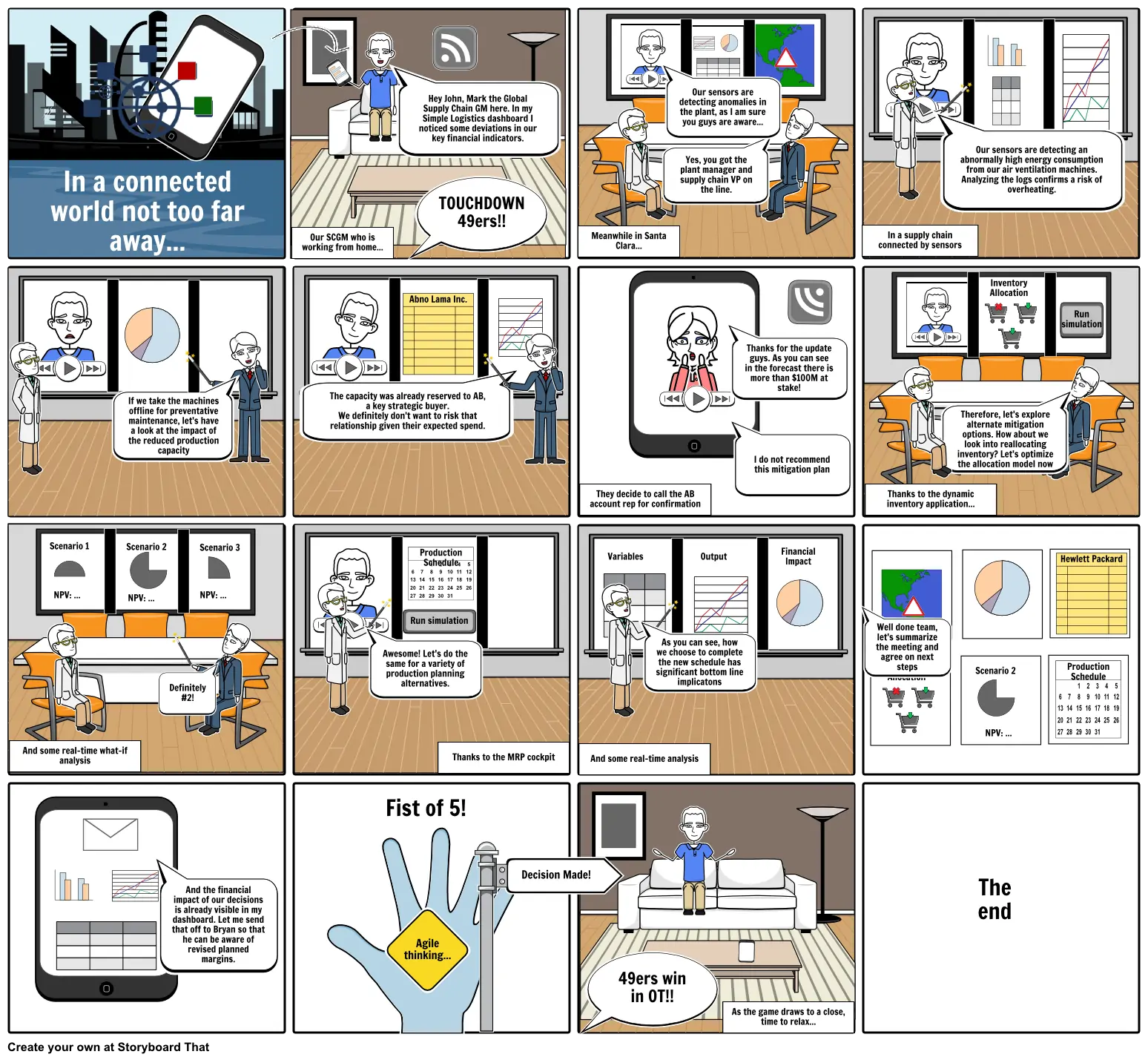

Operations Control of the Future

Texto del Guión Gráfico

- In a connected world not too far away...

- Our SCGM who is working from home...

- Hey John, Mark the Global Supply Chain GM here. In my Simple Logistics dashboard I noticed some deviations in our key financial indicators.

- TOUCHDOWN 49ers!!

- Meanwhile in Santa Clara...

- Our sensors are detecting anomalies in the plant, as I am sure you guys are aware...

- Yes, you got the plant manager and supply chain VP on the line.

- In a supply chain connected by sensors

- Our sensors are detecting an abnormally high energy consumption from our air ventilation machines. Analyzing the logs confirms a risk of overheating.

- Inventory Allocation

- Scenario 1

- If we take the machines offline for preventative maintenance, let's have a look at the impact of the reduced production capacity

- Scenario 2

- Scenario 3

- The capacity was already reserved to AB, a key strategic buyer. We definitely don't want to risk that relationship given their expected spend.

- Abno Lama Inc.

- They decide to call the AB account rep for confirmation

- Thanks for the update guys. As you can see in the forecast there is more than $100M at stake!

- I do not recommend this mitigation plan

- Thanks to the dynamic inventory application...

- Therefore, let's explore alternate mitigation options. How about we look into reallocating inventory? Let's optimize the allocation model now

- Run simulation

- And some real-time what-if analysis

- NPV: ...

- NPV: ...

- Definitely #2!

- NPV: ...

- Awesome! Let's do the same for a variety of production planning alternatives.

- Run simulation

- Production Schedule

- Thanks to the MRP cockpit

- And some real-time analysis

- Variables

- As you can see, how we choose to complete the new schedule has significant bottom line implicatons

- Output

- Financial Impact

- Well done team, let's summarize the meeting and agree on next steps

- Inventory Allocation

- Scenario 2

- NPV: ...

- Production Schedule

- Hewlett Packard

- And the financial impact of our decisions is already visible in my dashboard. Let me send that off to Bryan so that he can be aware of revised planned margins.

- Fist of 5!

- Agile thinking...

- Decision Made!

- 49ers win in OT!!

- As the game draws to a close, time to relax...

- The end

Más de 30 millones de guiones gráficos creados